Roller chains Drive chains Conveyor chains Attachment chains Leaf chains Welded chains Cast iron chains Chains for water treatment systems Sprockets for conveyer chains Sprockets for roller chains Chain tensioners Elevator buckets Vibrating conveyors Accessories

A variety kinds of sprocket wheels are available, such as sprocket wheels for power transmission roller chains, malleable chains and conveyor chains. The chains are driven smoothly with little wear and with small power consumption due to Hitachi Sprocket Wheel with utmost precision in dimension and high resistance to abrasion.

Mismatching of chain and sprocket will hurt smooth operation as well as shortening life of both chain and sprocket. Important points for sprocket are as follows.

The sprocket we manufacture is based on many years of design experience. Ductile cast iron (FCD600) is the standard material of sprockets for cast chain. If the application requires, we also manufacture sprockets with surface hardened tooth tips for higher wear resistance.

Conventional type sprocket for plastic chain was combination of plastic teeth and cast iron boss, which brought heavier weight and corrosion at boss area. All plastic assembly type sprocket was developed to solve these problems.

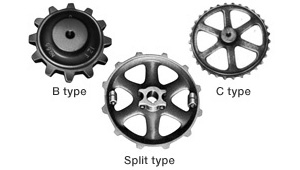

Replaceable segment teeth sprocket is composed of main body and one piece type of segmented teeth insert bolted to the body. Main body is made of structural steel, and teeth inserts are made of stainless steel or plastic. Segmented teeth inserts can be replaced by only removing bolts.